Total station search

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

Hydraulic cylinders can be divided into two types: single-layer type and combination type according to their structure.

① The wall of the single-layer cylinder is composed of a whole set of materials in the thickness direction, that is, the wall of the cylinder needs only one layer (to prevent the internal medium from corrosion, the anticorrosive layer on the lining is not included). Single-layer cylinders can be divided into single-layer coil welding type, overall casting type, forging welding type, and non-welding bottle type according to the manufacturing method.

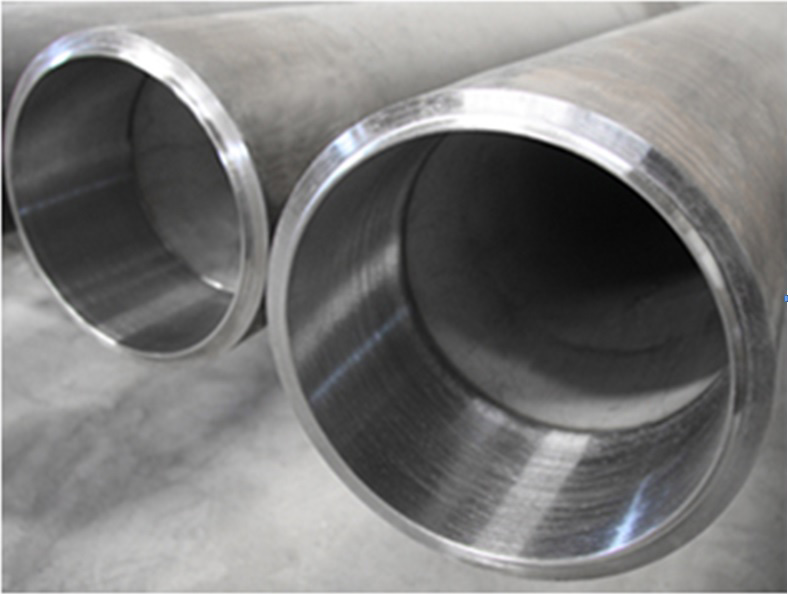

In the meantime, the single-layer roll-welded structure is a cylinder method that is currently produced and used the most. It uses steel plates to be rolled into a cylinder on a large coil rolling machine, and is welded into longitudinally welded seams to become cylinder sections. The blue is assembled and welded into a container. The cylinder shown in Figure 1-1 is a single-layer roll-welded structure.

The whole cast-type structure is the earliest choice of cylinder method. The cylinder and flange can be forged into one body or connected with threads during production. The entire cylinder body has no welds. After the development of welding skills, segmented casting was presented, and then the whole forged welded cylinder was welded together.

There are two main production methods for non-welded bottle cylinders: one is made of seamless steel pipe through hot-spinning necking at two ends; the other is the steel ingot after hot-spinning necking. Generally, the whole cast and forged welded cylinders are mainly used in high pressure and high pressure vessels, while non-welded bottle cylinders are often used to make non-welded large-volume bottle pressure vessels .

The metallographic arrangement of the whole cast cylinder is dense and high in strength, so the quality is good, and it is especially suitable for high pressure vessels made of high strength steel with poor welding function.However, the smelting, forging and machining equipment that requires a lot of time during production, the data consumption is large, the steel utilization rate is low (only 26% ~ 29%), and the amount of mechanical processing is large, so it is generally only used for inner diameters of 300 ~ 800mm, Small high-pressure vessels with a length not exceeding 12m, such as polyethylene reactors, artificial crystal kettles, etc.

② The wall of the combined cylinder is composed of two or more layers of materials that are not connected to each other in the thickness direction. According to the structure and manufacturing method, the combined cylinder can be divided into two types: multi-layer and surround.