Total station search

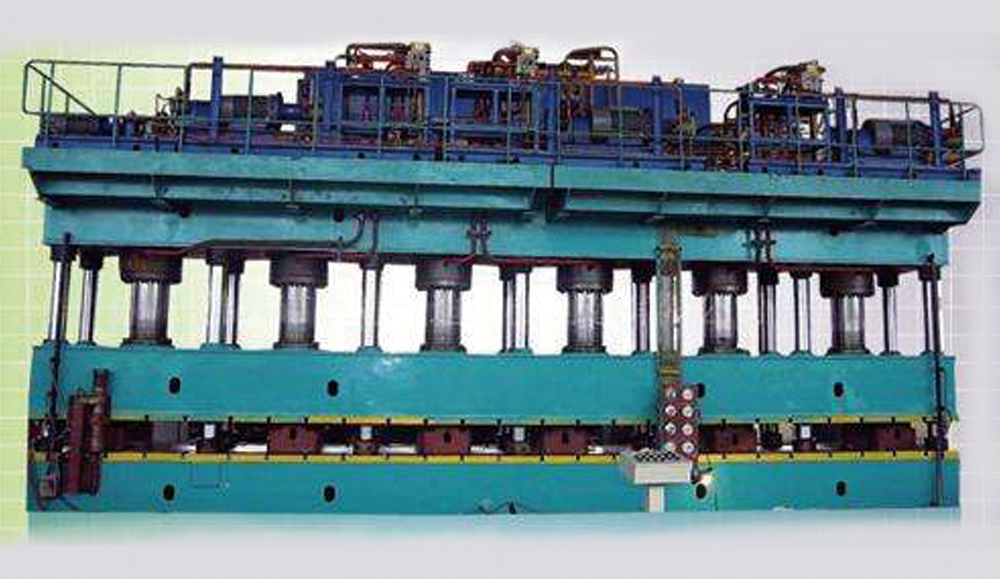

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

Operating pressure test procedure

View before experiment

1. Check that the pressure gauge specification fits the experimental range, and within the useful calibration period.

2. Check that the pressure pump is intact, and that the pump and the experimental site are receiving smoothly.

3. Check that all electrical switches, electrical appliances, and wiring are intact, and the shell has a secure and reliable grounding device.

4. Check whether there is any defect in the appearance of the workpiece being tested. There are no scratches or bumps on the flameproof surface. All fasteners must be tightened and must not be loose.

Steps

1. The tooling of the survey window on the equipment case, the introduction of equipment, etc. are fastened tightly, and the sealing rubber pad equipment is correct to ensure that no leakage occurs.

2. Place the flameproof casing flat on the hydraulic table tooling to ensure that the sealing rubber pad is tightly combined with the casing and experimental tooling, and then fasten the compaction equipment evenly.

3. Connect the water inlet valve, the water pressure tester water pipe and the pressure gauge to the housing.

4. Open the water inlet valve and fill the case with water.

5. Open the upper exhaust valve and start the hydraulic pressure testing machine. After the exhaust valve overflows, close the exhaust valve.

6. Slowly add pressure, pay attention to investigating the changes in the shell, and find abnormalities, and immediately stop the hydraulic pressure tester.

7. Investigate the pressure gauge. When the pressure increases to 1.0Mpa, close the hydraulic pressure tester and the water inlet valve.

8, start the chronograph stopwatch, which lasted 1min, there was no continuous water leakage within 10S, and there was no structural damage to the shell, which was in line with the specifications and the shell test was qualified.

9. If quality problems are found during the experiment, they should be marked and repaired after the pressure is removed. Prevent welding, hitting, tightening screws and other operations under pressure operation.

10. The experimenter should make the hydraulic pressure record and the shell number, and submit it to the quality assurance department for archiving.

Precautions

1. After the hydrostatic test is completed, the power supply should be cut off, the site should be cleaned up, tools should be organized, tooling should be set up, and the relevant parts of the pressure testing equipment should be oiled and maintained to prevent corrosion.

2. The pressure gauges used for water pressure experiments must not be replaced. They should be properly kept and regularly checked.

3. The hydraulic pressure experiment is operated by a special person. During the experiment, unrelated personnel are prevented from entering the work site.

4. Jumping pressure is not allowed during the experiment, and it should be smoothly and gradually lowered during pressure reduction to prevent water pressure from damaging the seal of the pipe joint.