Total station search

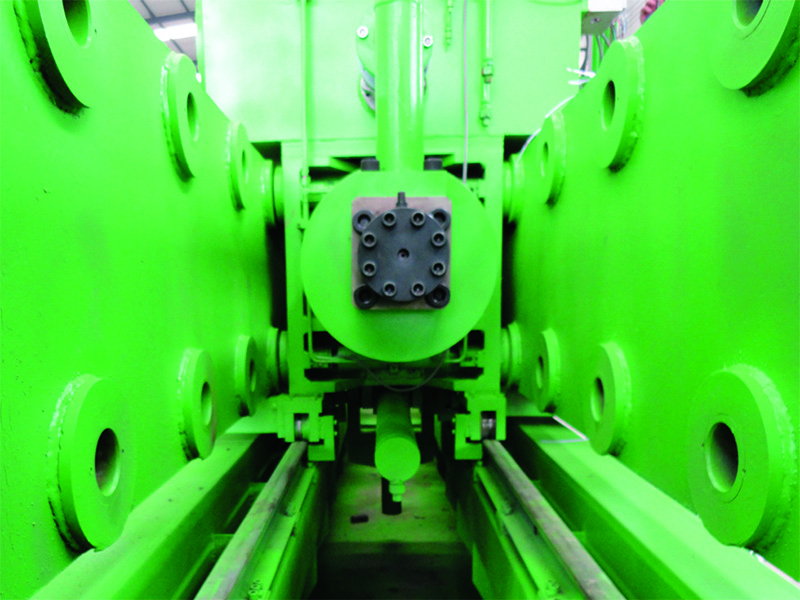

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

Maintenance method of steel pipe hydraulic pressure testing machine

I. Daily maintenance

1. After the steel pipe hydraulic pressure testing machine equipment is used, remove the oil, dirt and water residue on the surface of the blind plate and the body.

2. After each use of the equipment, remove the pressure of the hydraulic system and the test medium system, and remove the water in the water storage tank.

3. After each use of the equipment, fill a suitable amount of lubricant to the moving parts of the equipment.

4. Before using the equipment, check whether the connection of each air pipe joint is good, and whether there is air leakage or oil leakage. Whether the high-pressure pipe is flawless and damaged.

5. Before using the equipment, check that the water level of the water storage tank is at the height of 2 / 3-4 / 5 of the water tank;

6. Before using the equipment, check whether the pressure gauge returns to zero under air pressure.

7, if the equipment has not been used for a week, refer to the above 1-6, maintenance once a week.

Second, monthly maintenance

1. Check the hydraulic oil level of the hydraulic system, in a reasonable position (above zero).

2. Check that the hydraulic cylinder is in a state of no oil leakage.

3. Check and maintain the screw locking of the device.

4. Check and maintain the equipment for rust, and add protective oil to the rust-prone parts such as the operating table.

5. Check and maintain the power supply and ground wire of the equipment in a qualified condition.

Third, the annual maintenance:

1. Replace the equipment oil pump filter and water pump filter.

2. Clean the fuel tank and replace the hydraulic oil.

3. Verify the pressure gauge.