Total station search

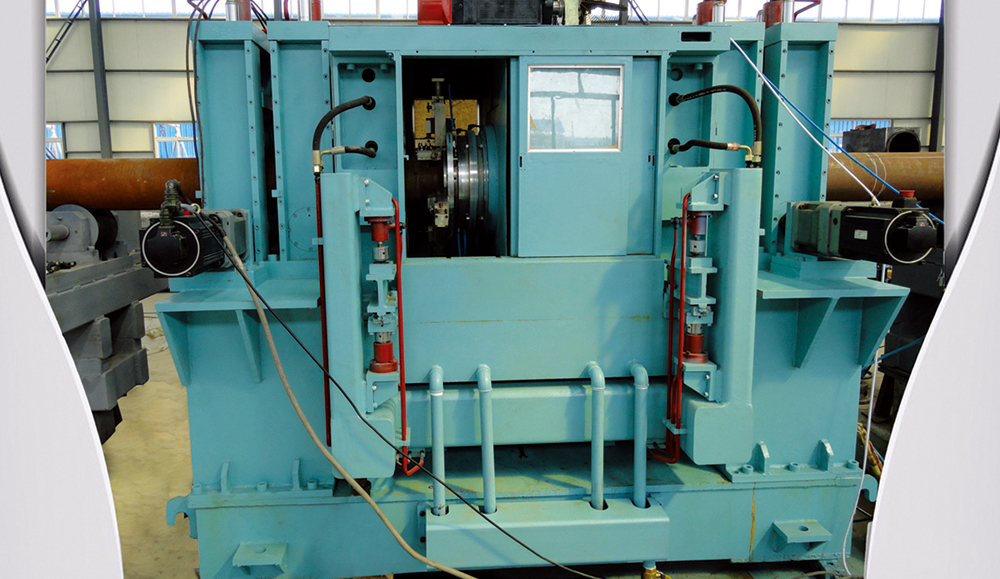

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

1. Equipment outline

Hydraulic press is a kind of machine that uses oil-water balance control to carry out hydrostatic test on steel pipe. It is mainly composed of the following parts: steel pipe conveying equipment, water system, oil system and control system. The main feature of the hydraulic press is the large working stroke, which can apply working force to the workpiece during the full stroke, and it can more effectively forge large-section forgings without huge impact and noise, better labor conditions, and less environmental pollution. The basic operating principle of the hydraulic press is Pascal's law, which uses water as the working medium and works with static pressure transmission.

2. Analysis of fault phenomena and causes

There are many reasons for the thread of the hydraulic press column to wear, but there are two main reasons. One is because during the long-term operation of the casting process, the nut is loosened under the effect of pain and frequent alternating load, and the nut moves up and down under load. The thread of the column changed from receiving static pulsating cyclic stress to receiving impact stress, which caused the thread to deform, wear and even cut off; the second was repeated water immersion of the thread for a long time, which caused the thread to rust or reduce its strength.

3. Comparison between traditional correction method and Fu Shilan field correction method

3.1 Traditional correction methods

For the thread problem, the traditional treatment method is to correct the machining after thermal spraying or to cut the original thread and process the new thread from scratch, but both have certain disadvantages. The thermal stress of thermal spraying at high temperatures cannot be completely eliminated, which is likely to cause raw material damage, causing parts to show twists or fractures. Newly sprayed threads are easy to fall due to the influence of shear force; turning the original thread to process the thread from scratch, not only takes time It is labor-intensive and needs to be equipped with the corresponding split nut from scratch.

3.2 Advantages and Feasibility Analysis of Fushilan Field Correction

Fu Shilan polymer composite material 2211F is a high temperature, strong corrosion resistant and machineable metal correction and protection composite material. This material has outstanding adhesion and mechanical functions. It not only has the strength and hardness of metal, It also has concessions. After the correction, it can not only satisfy the required accuracy and strength, but also reduce the shock and vibration received by the equipment during operation, and it can satisfy the requirements of the equipment to accept various composite forces during operation. After fast construction in the field, the worn-out thread can be corrected online. The application skills of polymer composite materials can enable companies to quickly and usefully make on-site corrections at the top of the list, effectively prevent the loss of benefits caused by long-term equipment shutdowns and production shutdowns, and effectively prevent general costs such as transportation costs and hoisting to ensure construction personnel Personal safety. The selection of polymer composite data is attributed to cold welding skills. There are no problems such as thermal stress, which can effectively prevent secondary damage to the substrate. This type of correction data is more reliable with Fu Shi Blue Metal Correction Data 2211F.