Total station search

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

Steel pipe hydraulic press is a kind of machine that uses oil-water balance control to carry out hydrostatic test on steel pipe.

It mainly consists of the following parts: steel pipe conveyor, water system, oil system and control system.

Caliber of steel pipe: Φ108-Φ2000

Test water pressure: 6Mpa-30Mpa

Length of steel pipe: 6m-18m.

1, steel pipe pressure testing machine uses and characteristics

Steel pipe pressure testing machine is a dedicated device for steel pipe pressure testing, the apparatus is mainly different diameters of stainless steel pipe, steel pipe for pressure and Longitudinal test.

The hydraulic press uses two liftable rollers to support the steel pipe under test, and the steel pipe is compressed between the fixed push plate and the movable tight plate by the main oil cylinder, so that the pipe ends of the steel pipe are sealed. Relying on high-flow low-pressure pump to complete water intake, and then using high-pressure pump to complete the pressure test.

2. Structure and working principle of steel pipe hydraulic pressure testing machine

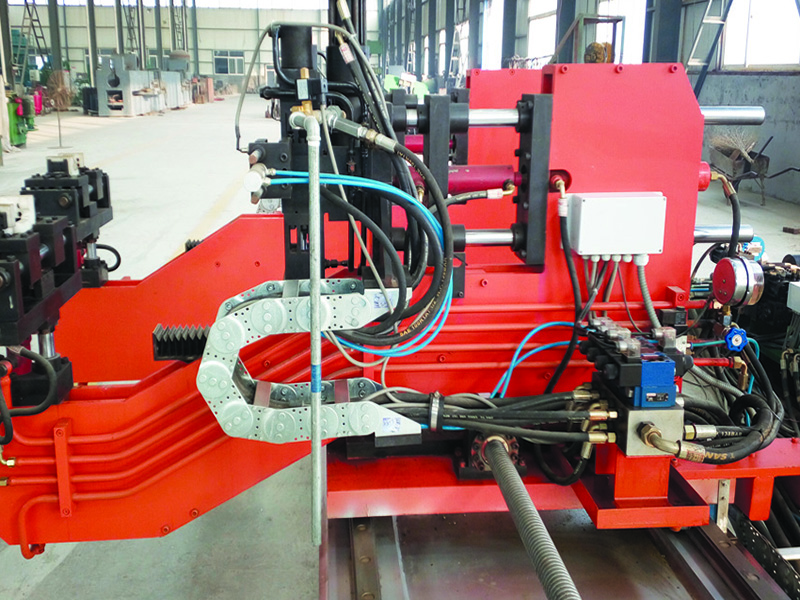

The equipment consists of a cylinder support, a fixed plate, a movable push plate, a beam, a supporting roller, a feeding mechanism, a feeding mechanism, a hydraulic system, a hydraulic system, and an electrical control system.

(1) Cylinder bracket

The cylinder support is used to support the cylinder. The cylinder is responsible for pushing the movable push plate during work.

(2) Fixed plate

The fixing plate is welded by high-quality carbon steel plate, which is located at the end of the equipment and welded with the beam. The center of the board is equipped with a water inlet pipe through which a water pump injects water into the steel pipe under test.

(3) Active pusher

The movable push plate is placed at the other end of the device, and is pushed by the main oil cylinder to compress the pipe end of the steel pipe under test to achieve sealing. A water pipe is installed on the movable push plate for observing whether the steel pipe under test is filled with water. When the end of the movable push plate evenly overflows water, it means that the steel pipe is full of water. The low-pressure pump should be stopped and the high-pressure pump should be used to press the water.

(4) Girder

There are 4 beams in total, which are responsible for connecting the cylinder bracket and the fixing plate. At the same time, it also acts as a guide and track for the movement of the movable push plate. The girders are subject to great tensile stress during work and need to have sufficient strength.

(5) Support roller

There are two supporting rollers, which are placed between the movable push plate and the fixed plate, and are responsible for holding the steel pipe under test. The supporting roller is moved up and down by the oil cylinder to adjust the placement position of different steel pipes in the hydraulic press.

(6) Hydraulic system

The hydraulic valve parts used in the hydraulic system of this equipment are selected from domestic quality manufacturers to ensure safe and reliable operation. Hydraulic system includes hydraulic station, valve group, hydraulic pipeline and accessories.

(7) Hydraulic system

The hydraulic system is composed of a low pressure system and a high pressure system. The low-pressure system is composed of two large-flow multi-stage submersible pumps and corresponding pipelines, and the test steel pipe is filled with water in the shortest time. The high-pressure system consists of a plunger high-pressure water pump and corresponding pipelines, and the water pressure can reach 25MPa. The hydraulic pneumatic system consists of a hydraulic station, a liquid filling system, control valves, pipelines and accessories.

(8) Electric control system

The electronic control system uses a programmable controller (PLC) to control the equipment, with accurate control and high degree of automation. The electrical measurement and control system includes a main power cabinet, an operation console (PLC), and field sensors.