Total station search

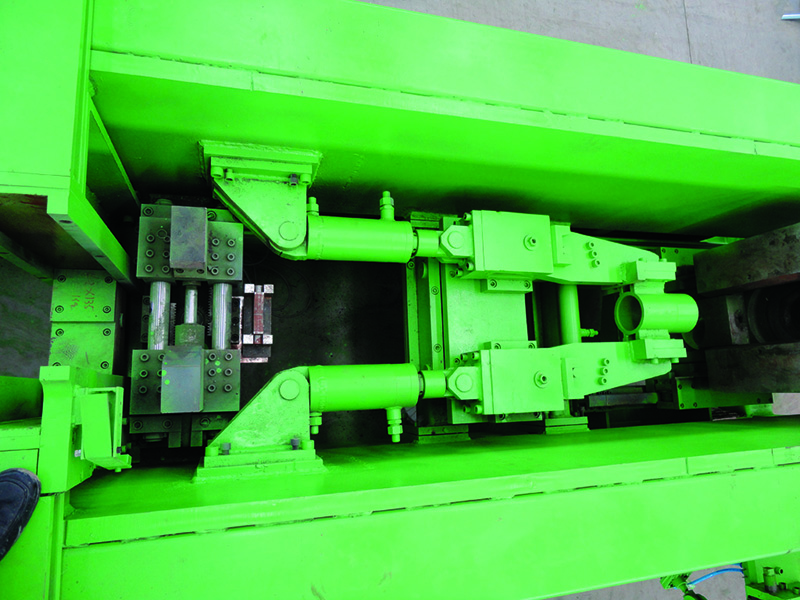

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

The imported hydraulic pressure testing machine is a fully active steel bar processing production line that cuts, transports, and stores.

Product Category: Multifunctional CNC Bending Hoop Machine

1. This equipment can cut I, II, III, IV and other high-strength ribbed steel bars.

2. Fully active rebar processing production line integrating cutting, transporting and storage.

3. Widely used in steel processing plants, bridges, highways, railways and nuclear power construction.

Product introduction of CNC hydraulic steel bar cutting production line:

1. This equipment can cut high-strength ribbed steel bars such as I, II, III, and IV.

2. Widely used in steel processing plants, bridges, highways, railways and nuclear power construction.

3. Fully active rebar processing production line integrating cutting, transporting and storage.

feature of product:

Shearing, transporting, and storage in a fully active rebar processing production line.

1. The cutting roller table is controlled by imported PLC, and the movable track and fixed baffle have high accuracy.

2. Hydraulic shearing system, low failure rate, high reliability and strong shearing ability.

3. Multi-baffle design, fast positioning speed and high power.

4. Two-way receiving organization, the product storage volume has doubled.

5. Configuration of tailoring can greatly improve the utilization of data.

6. Control system: PLC, inverter, touch screen.

The CNC cutting production line is a device for cutting rods to a fixed length. It replaces the original single-machine cutting method and has the functions of active transmission, positioning, and collection of steel bars. The cutting line has high precision, high transmission power, high efficiency and reliability, and a variety of storage methods are used for product collection, which reduces the dependence on lifting equipment.

CNC cutting production line shows its superiority when processing large-diameter and large-volume steel bars. When the batch of the same specification is large, multiple shears can be performed at the same time with a cutting line, and the power is significantly improved. When the diameter of the steel bar is large, the labor intensity of manual transfer processing using traditional equipment is very large. After using this equipment, the labor intensity is greatly reduced, and the production power is greatly improved while the safe production is guaranteed.