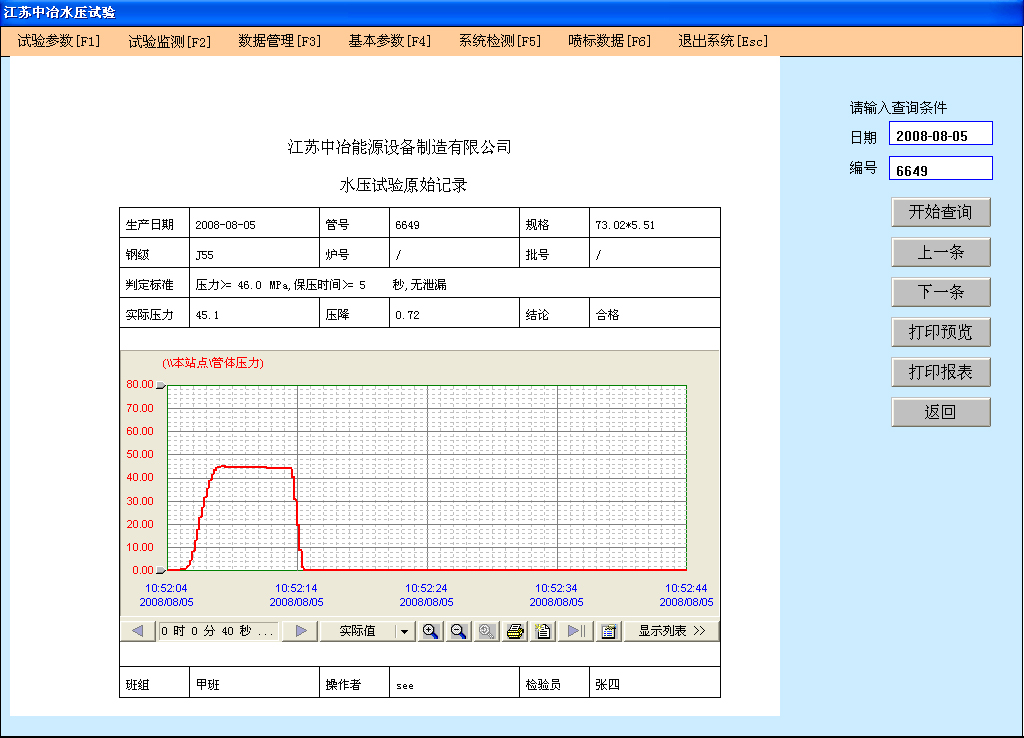

Total station search

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

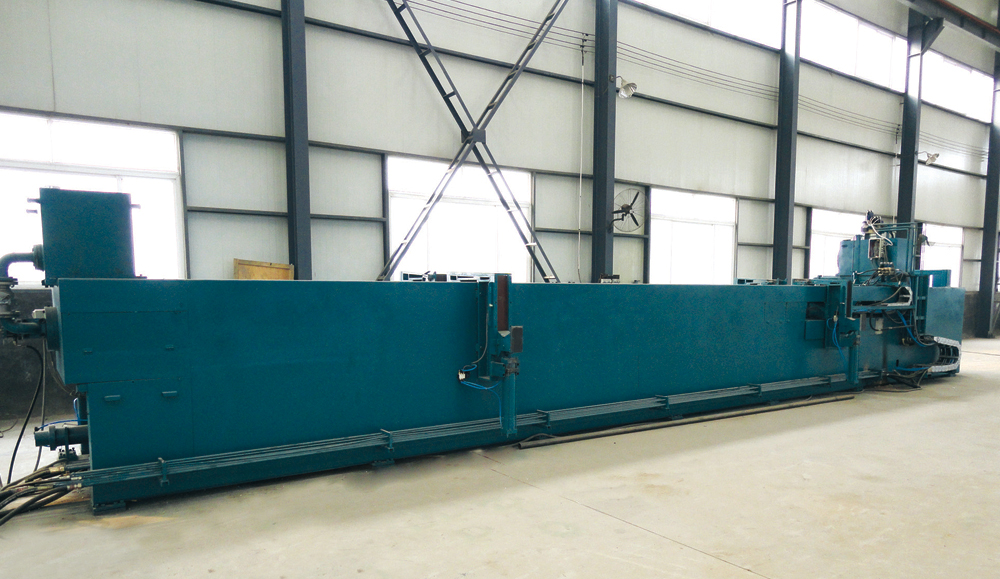

This equipment adopts a frame-type four tension beam structure, a radial large-gap seal form, an oil-water booster-type waterway design, a double V-shaped centering clamping mechanism, and a double moving head design. The tested tubes only need to replace the seals and the spacers and baffles in the head; industrial computer control can not only print the test results in real time, but also manage and query the historical data of the test; the equipment has a reasonable structure, reliable performance and high production efficiency .

Manufacturers using this type of hydraulic press include: Russia TEMERSO Engineering Co., Ltd., Andong Petroleum (Xinjiang Tong'ao Oilfield Technology Services Co., Ltd.), Tianjin Dehua Petroleum Equipment Manufacturing Co., Ltd., Bazhou Hongyuan Petroleum Equipment Equipment Co., Ltd., Tailongxing Drilling & Production Parts Repair Co., Ltd., Panshi Zhucheng Seamless Steel Tube Co., Ltd., Dongying Bocheng Petroleum Equipment Co., Ltd., Jiangsu Shengda Petroleum Equipment Manufacturing Co., Ltd., Mengcun Hui Autonomous County Guanqun Pipe Industry Co., Ltd. The host is shown in Figure 1.

Figure 1-Top inlet and outlet type hydraulic test machine

Test tube diameter (mm) | Ф60.3∽Ф273 | Test tube length① (mm) | 6000∽13000 |

Working beat ② (s / root) | 45s∽70 | Station | Single station |

Turbocharger rated pressure (Mpa) | 70∽120 | compress time | 5s∽300s |

Note:

① Design a technical solution according to user requirements. The minimum length of the tested tube is 5000mm and the longest can be up to 15000mm.

② The working cycle is related to the diameter of the tube being tested. Smaller tube diameters require less time and larger tube diameters require longer time.