Total station search

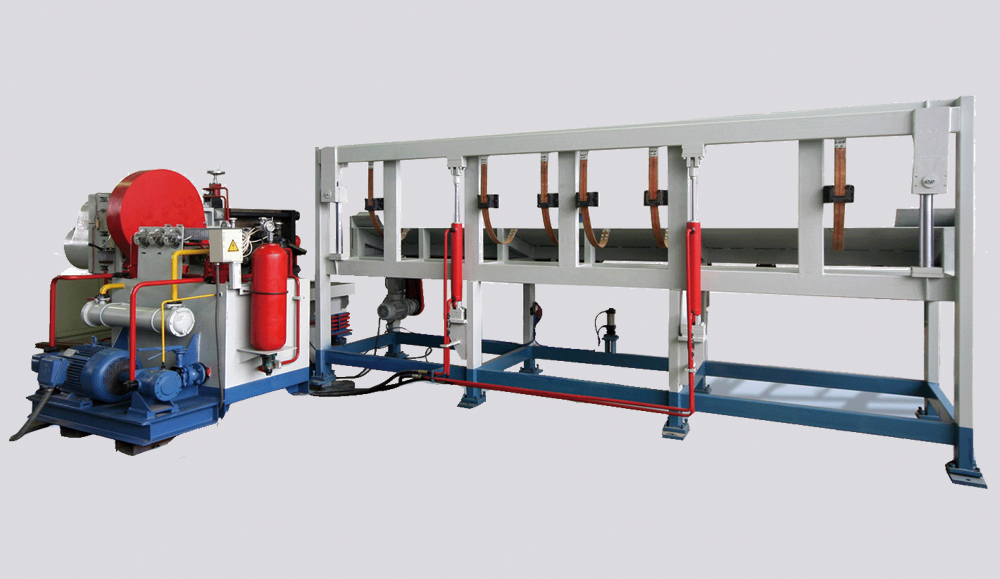

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

I produced the BCH / JBJ-type full- automatic precision bar shear is for the engine exhaust valves industry resistant stainless steel (austenitic stainless steel) precision cutting research and development of special equipment, engine valve industry has been well-known foreign-controlled enterprises Adopted and recognized, with world advanced level.

As we all know, austenitic stainless steel for valve materials has high strength, high toughness, and high hardness in the state of supply. The products cut by the traditional punching and cutting method have severe deformation and cannot meet the requirements of the electric upsetting process. At present, most of the industries use abrasive wheel cutters to cut the material. This method wastes materials, pollutes the environment, and harms the health of workers.

BCH / JBJ type full-automatic precision bar shears include the basic components such as the machine base, as well as the cloth, feeding, feeding, clamping, cutting, and dividing mechanisms. The feeding part is provided with a blank length measuring mechanism to measure the length of the blank, which improves the reliability of the conversion of the blank head and tail. The active cutter head uses a crank-slider type, the counter-cut power head and other actions are controlled by liquid and gas, and the feeding and feeding motors are controlled by variable frequency motors. The whole machine has a strong structure, reliable installation and low impact.

BCH / JBJ.C bar shearing principle:

During the feeding of the bar material, the blocking mechanism makes the bar material reach a fixed length, the clamping cylinder pushes the wedge block to advance the clamping block to clamp the bar material, and the flywheel drives the crankshaft to impact the punch pad to push the punching slider to make the tool pair The bar material is sheared, the bar material is cut off, and at the same time, the floating oil cylinder moves backward with the bar material floating.

The BCH / JBJ.C bar shear removes the reverse cutting function, so the equipment correspondingly removes the following mechanisms:

1. Reduce the width of the moving slide and change its overall slider to a two-part slider of a die-cut slider and a die-cut floating slider;

2. Remove the clamping mechanism of the original slider;

3. Since the original sliding block is divided into two parts, it is replaced with a punching slide block and a floating slide block, which eliminates the two sets of centering cylinder systems originally designed;

4. Because the backcut is removed, the original equipment's moving slider backcut amount adjustment wedge and the cylinder driving part are omitted;

5. Due to the removal of the reverse cutting, the blade was changed from the original four blade to two blade;

6. Since the equipment removes the reverse cutting, the action is greatly simplified, the installed power is reduced, and the action is simplified. The cooler of the hydraulic system is changed to an air-cooled cooler.

Based on the original BCH / JBJ.A-40t, some improvements have been made to its reserved parts.

1. Change the electromagnetic clutch on BCH / JBJ.A-40t from the crankshaft (low speed shaft) to the flywheel wheel (high speed shaft) to reduce the friction of the friction clutch and increase the clutch life;

2. Increase the length measurement function of the blank, which is more suitable for the working environment where the length of the domestic blank is inconsistent;

3. Improved the design of other unreliable links of BCH / JBJ.A-40t;

4. Due to the simplified action, the work efficiency is increased to 30 pieces / min;