Total station search

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

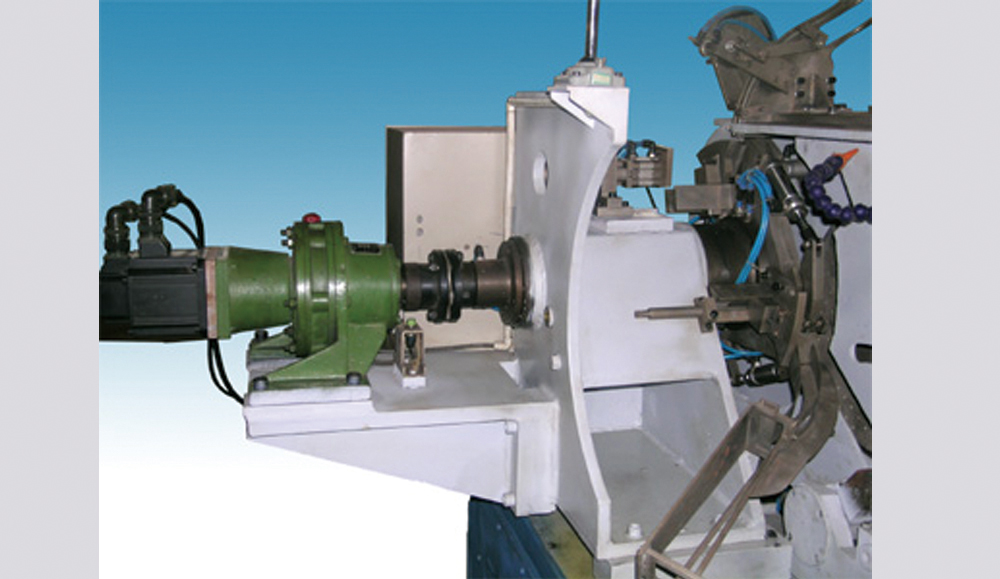

MD-type valve rod end surface grinder is a special type of valve rod end surface grinder. It is a product redesigned after our company digests and absorbs foreign equipment. This product not only has the function of automatic loading and unloading of foreign products, but also the workpiece turntable is driven by a servo motor and rotates step by step. Compared with foreign swing and rotary workpiece discs, it has the following characteristics:

1. Static loading and unloading, static positioning and clamping (swing type is dynamic loading and unloading, dynamic positioning), reliable movement and high positioning and clamping accuracy.

2. The cutting speed of workpiece (rotating speed of workpiece disc) is continuously adjustable, which facilitates rough and fine machining selection.

3. Static loading and unloading greatly simplifies the tooling molds for valves of different specifications, and is easy to install and adjust, which is convenient for changing the specifications of the workpiece.

4. High processing efficiency.

In order to ensure the unification of the valve design basis and the process basis, this equipment uses the valve cone or bottom positioning method to grind the end face of the small head with accurate positioning and high machining accuracy. Suitable for roughing and finishing of small end faces of intake and exhaust valves.