Total station search

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

Straight seam steel pipe is a steel pipe with welds parallel to the longitudinal direction of the steel pipe.Hydrostatic testing machines are generally divided into metric electric welded steel pipes, welded thin-walled pipes, transformer cooling oil pipes, and so on. The production process of straight seam welded pipe is simple, with high production power, low cost and rapid development. The strength of spiral welded pipes is generally higher than that of straight seam welded pipes. Welded pipes with larger diameters can be produced from narrower billets. Welded pipes with different diameters can also be produced with billets of the same width.However, compared with the straight seam pipe of the same length, the weld length is increased by 30 ~ 100%, and the production speed is lower. According to the production process, straight seam steel pipes can be divided into high frequency straight seam steel pipes and submerged arc welded straight seam steel pipes. Submerged arc welded straight seam steel pipes are further divided into UOE, RBE, JCOE steel pipes according to their different forming methods. The following describes the common high-frequency straight seam steel pipe and submerged arc welded straight seam steel pipe forming processes.

1. Plate exploration: After the steel plate used to make large-diameter submerged arc welded steel pipes enters the production line, the whole plate is firstly subjected to ultrasonic inspection;

2. Milling: Double-sided milling of both sides of the steel plate by an edge milling machine to reach the required board width, parallelism of the board edges and the shape of the groove;

3. Pre-bending: use a pre-bending machine to pre-bend the board edge so that the board edge has the curvature that meets the requirements;

4. Forming: On the JCO forming machine, first half of the pre-bent steel plate is repeatedly pressed into a "J" shape through repeated step punching, and then the other half of the steel plate is equally zigzag and pressed into a "C" shape, forming an " O "shape

5. Pre-welding: The formed straight seam welded steel pipe is welded and gas maintenance welding (MAG) is selected for continuous welding;

6. Internal welding: use multi-wire submerged arc welding (four wires can be used) inside the straight seam steel pipe for welding;

7. Outer welding: Column multi-wire submerged arc welding is used on the outside of straight seam submerged arc welded steel pipes for welding;

8. Ultrasonic inspection Ⅰ: 100% inspection of the front and back welds of the straight seam welded steel pipe and the base metal on both sides of the weld;

9. X-ray inspection Ⅰ: 100% X-ray industrial television inspection of the welds on the surface and the surface, using an image processing system to ensure the sensitivity of flaw detection;

10. Expansion: Expand the diameter of the submerged arc welded straight seam steel pipe to improve the dimensional accuracy of the steel pipe and improve the distribution of internal stress of the steel pipe

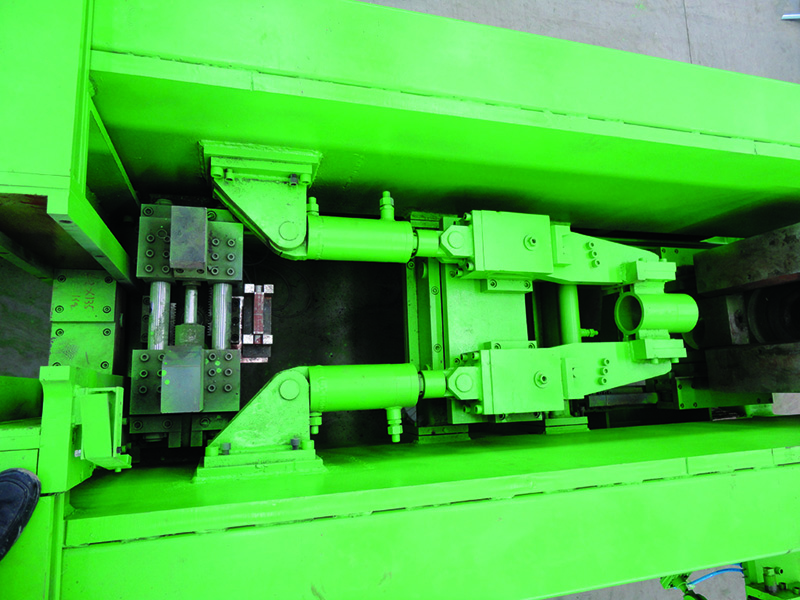

11. A hydraulic test : In the hydraulic test machine after the pipe-by-diameter steel pipe reaches the root check to ensure that the test pressure specifications, it has a function to record and store active;

12. Chamfering: Pipe end processing is performed on the steel pipe that passes the inspection to reach the required pipe end bevel size;

13. Ultrasonic inspection Ⅱ: Perform ultrasonic inspection one by one to check the shortcomings of the straight seam welded steel pipe that may occur after diameter expansion and water pressure;

14. X-ray inspection Ⅱ: X-ray industrial television inspection and tube-end weld seam filming of the steel pipe after the diameter expansion and hydraulic pressure experiments;

15. Tube end magnetic particle inspection: Perform this check to find tube end defects;

16. Anti-corrosion and coating: The qualified steel pipe is anti-corrosion and coated according to user requirements.