Total station search

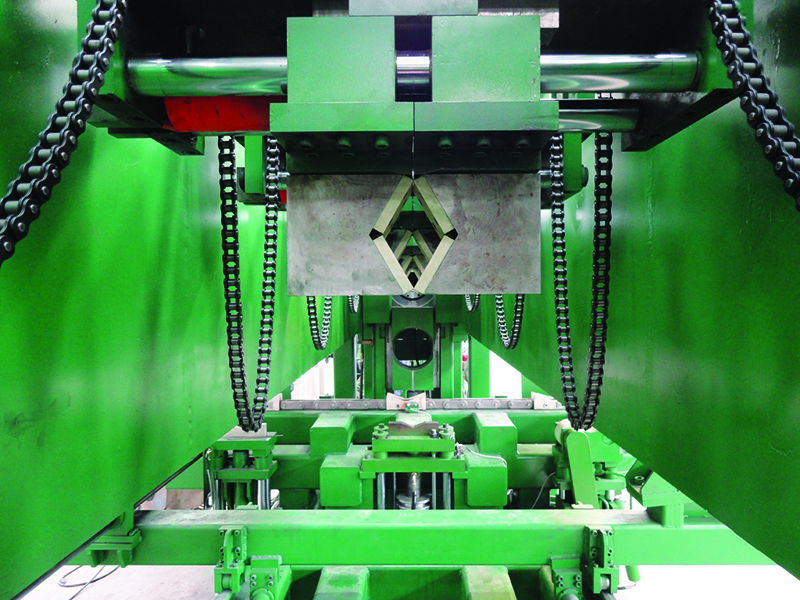

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

Production process of seamless steel pipe

The production process of general seamless steel pipes for steel pipe hydraulic pressure testing machinescan be divided into two types: cold drawing and hot rolling. The production process of cold rolled seamless steel pipes is generally more messy than hot rolling. The tube blank must first be three-roll continuous rolling. After kneading, a sizing test is performed. If the appearance does not respond to cracks, the round pipe is cut by a cutting machine and cut into a blank of about one meter in length. Then enter the annealing process. Annealing should be acid-washed with an acidic liquid. When pickling, leave an accidental table to indicate whether there is a large amount of blistering. If there is a large amount of blistering, it indicates that the quality of the steel pipe does not meet the specifications. The appearance of cold-rolled seamless steel pipe is shorter than that of hot-rolled seamless steel pipe. The wall thickness of cold-rolled seamless steel pipe is generally smaller than that of hot-rolled seamless steel pipe. However, the appearance looks brighter than that of thick-walled seamless steel pipe. It's rough, and it doesn't have too much burr. The delivery status of the hot-rolled seamless steel pipe is generally the hot-rolled status and the delivery is performed after heat treatment. After passing the quality inspection, the hot-rolled seamless steel pipe must be selected by the operators' rigorous skills. After the quality inspection, the surface is oiled, followed by repeated cold-drawing experiments. After the hot-rolling treatment, the perforation experiment is performed. If the perforation is too large, straightening correction is required. After straightening, it is transferred to the flaw detector by the conveying equipment for flaw detection experiments. It is labeled, standardized and placed in the warehouse.

Hot rolling (kneading seamless steel tube)

Round pipe billet → heating → perforation → three-roll diagonal rolling, continuous rolling or kneading → stripping → sizing (or reducing) → cooling → straightening → hydraulic test (or flaw detection) → symbol → storage seamless steel pipe It is made of steel ingots or solid tube blanks through perforation to make capillaries, and then made by hot rolling, cold rolling or cold drawing. The specifications of seamless steel pipes are indicated in millimeters of outer diameter * wall thickness. There are two types of seamless steel tubes: hot rolled and cold rolled (dial) seamless steel tubes. Hot rolled seamless steel pipe is divided into general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, geological steel pipe and other steel pipes. Cold rolled (dial) seamless steel tubes include general steel tubes, low and medium pressure boiler steel tubes, high pressure boiler steel tubes, alloy steel tubes, stainless steel tubes, petroleum cracking tubes, and other steel tubes. They also include carbon thin-walled steel tubes, alloy thin-walled steel tubes, Stainless steel thin-walled steel pipe and special-shaped steel pipe. The outer diameter of hot-rolled seamless pipe is generally greater than 32mm, the wall thickness is 2.5-200mm, the diameter of cold-rolled seamless steel pipe can reach 6mm, the wall thickness can reach 0.25mm, the outer diameter of thin-walled pipe can reach 5mm, and the wall thickness is less than 0.25mm. The rolling accuracy is higher than that of hot rolling.

Generally, seamless steel pipes are made by hot-rolling or cold-rolling with 10, 20, 30, 35, 45 and other carbon-bonded steels 16Mn, 5MnV and other low-alloy structural steels or 40Cr, 30CrMnSi, 45Mn2, and 40MnB combined steels. Seamless pipes made of low carbon steel such as 10 and 20 are mainly used for fluid transportation pipelines. 45, 40Cr and other medium carbon steel seamless pipes are used to make mechanical parts, such as the stress parts of cars and tractors. Generally, seamless steel tubes are used to ensure strength and flattening experiments. Hot-rolled steel pipes are delivered in hot-rolled condition or heat-treated condition; cold-rolled steel pipes are delivered in hot-treated condition.

Hot rolling, as the text suggests, the temperature of the rolled material is high, so the deformation resistance is small, and a large amount of deformation can be completed. Taking steel sheet rolling as an example, the thickness of the continuous cast slab is generally about 230 mm, and the thickness is 1 to 20 mm through rough rolling and finishing rolling. At the same time, because the steel plate has a small width-to-thickness ratio, the scale accuracy requirements are relatively low, and flatness problems do not occur briefly. It is mainly based on controlling convexity. Regarding the requirements of the arrangement, it is generally completed by controlling rolling and cooling, that is, controlling the rolling temperature and finishing temperature of finishing rolling. Round tube billet → heating → perforation → heading → annealing → pickling → oiling (copper plating) → Multi-pass cold drawing (cold rolling) → billet tube → heat treatment → straightening → hydraulic test (detection) → symbol → storage