Total station search

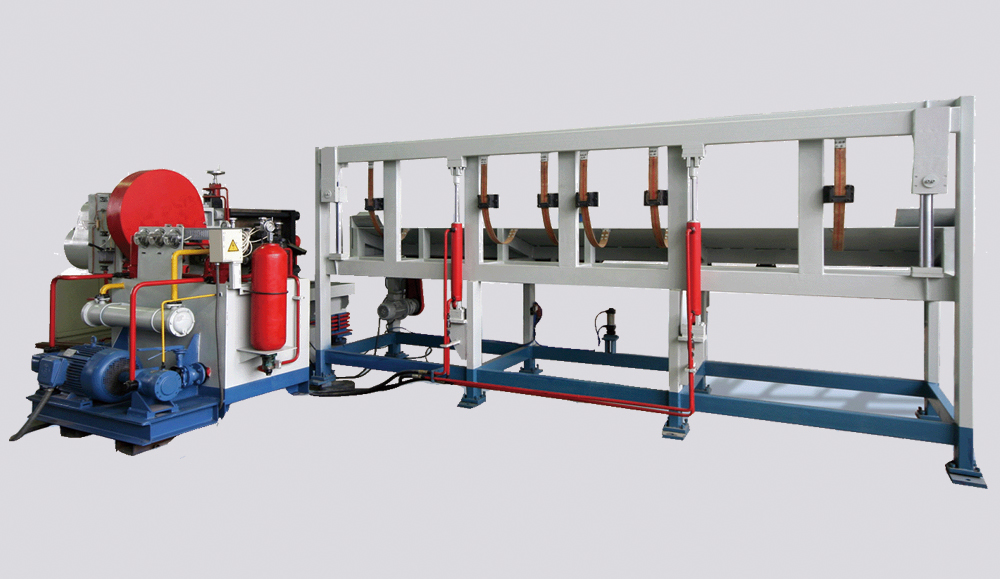

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

After the establishment of the new China in 1949, the construction of the heavy industry and the defense industry system was rapidly promoted, and these areas urgently needed large-scale forging equipment. The competent government department began to arrange the units that compensated for casting equipment in Japan. The Shenyang Heavy Machinery Plant and other units will make amendments to plan and build factories, masonry heating furnaces, heat treatment furnaces and other ancillary facilities.

In 1953, Shenyang Heavy Machinery Plant first compensated the 2000 tons (20MN) free forging hydraulic press scattered in Anshan and put the equipment into operation. This is the largest forging enterprise in China, and it is also the training of cadres, skilled personnel and workers for the production of large forgings. cradle. After repairing and compensating hydraulic presses in Japan, it has become one of the top companies in China that can plan and make casting hydraulic presses.

In 1954, after the compensation of the 10MN forging hydraulic press in Japan, the Taiyuan Heavy Machinery Plant, which was planned and built in China, was put into trial production. Another 12MN compensated by Japan was placed in Shanghai Pengpu Machine Factory after the forging hydraulic press was modified. Although these batches of foundry equipment are now outdated, most of the foundry hydraulic presses are steam-supercharged, with backward structures and poor functions, but they are all "national treasures" at that time.

In 1957, Taiyuan Heavy Machinery Plant installed two hydraulic presses, one was a 30MN hydraulic press imported from the Czech Republic, and the other was a 25MN free forging hydraulic press. The press was repaired by Shenyang Heavy Machinery Plant with a 30MN free forging hydraulic press compensated by Japan. . The original press lacked a base, the column had deep scars, and the diameter decreased after machining, and it was changed to 25MN after accounting.

When building the top heavy machinery factory, the Soviet Union originally planned to have only 8MN and 12.5MN free forging hydraulic presses. The Chinese government proposed that heavy machinery plants will not be able to produce large machinery and equipment without large casting hydraulic presses. After the decision that large forgings cannot be imported, the Soviet Union changed its plan to add a 60MN free forging hydraulic press imported from the Czech Republic. After the construction of the plant was completed, another 30MN free forging hydraulic press compensated by Japan was amended, and the equipment was at the end of the workshop. Because the surrounding area of the casting hydraulic press was too tight to produce, it was always put on hold. It was relocated to Luoyang Mining Machinery Factory in 1968 The 30MN free forging hydraulic press is still running.