Total station search

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

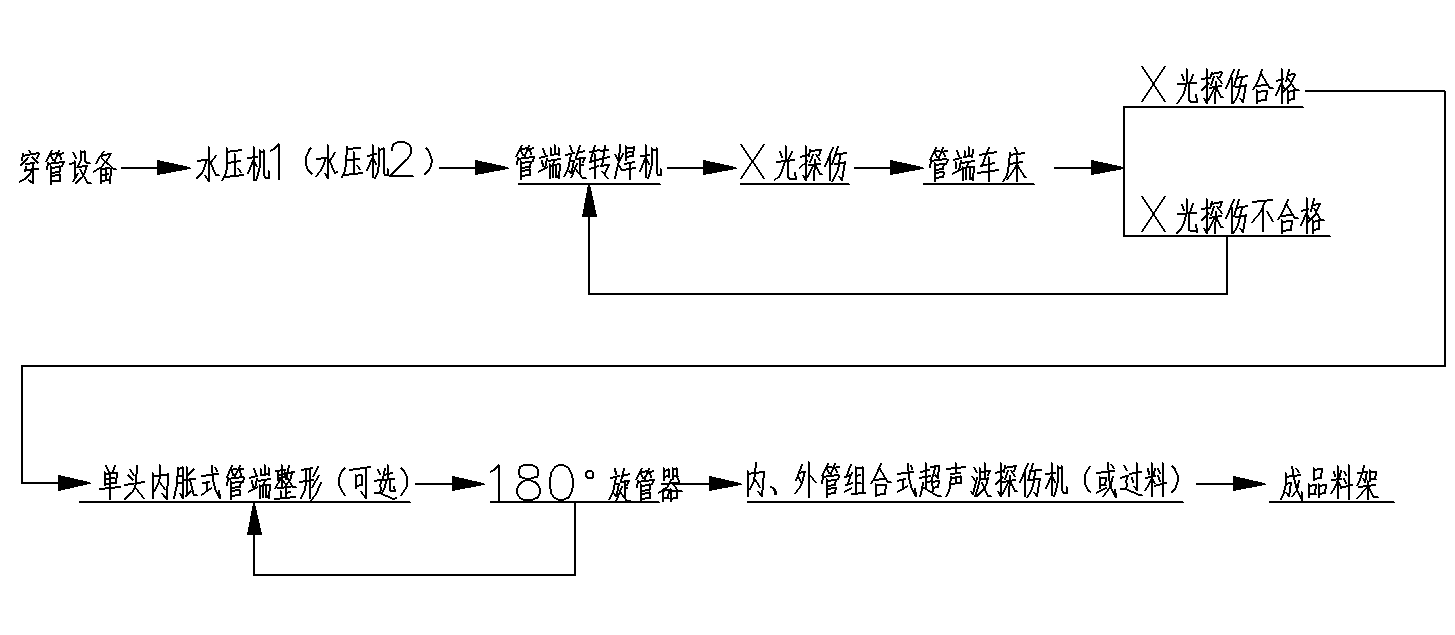

The equipment of this production line is arranged in accordance with API-5LD certification requirements. Full consideration is given to the process conditions and equipment utilization rate of each station in production. The space is reasonably arranged. The automatic production line has low labor costs, stable quality, and low energy consumption. Hydraulic internal expansion molding technology has the characteristics of excellent technology and technology, and simple and convenient operation; the unit mainly includes : pipe passing machine, tube expansion hydraulic press , hydraulic expansion machine, tube end rotary welding machine, tube end lathe, 1250t internal expansion tube End-shaping machine, combined inner and outer tubeultrasonic flaw detector (endoscope), X- ray flaw detector, 180 ° tube revolver, auxiliary machine, etc. The production line process is shown in the following figure:

1 ) The pipe-penetrating equipment will pass the inner pipe and the outer pipe together. Note that the inner surface of the outer pipe and the inner surface of the inner pipe are surface treated before entering the production line.

2 ), choose the expander hydraulic press ;

3 ) Enter the tube-end rotary welding unit for end-face sealing welding, and the two sets of welding machines weld the two ends of the pipe respectively;

4 ) Enter the X- ray inspection room for X- ray inspection and mark the inspection results;

5 ) The results of the testing will be labeled flat end surface chamfering or cutting the weld; X- ray inspection of the weld and failure of removal of the welding vehicle incision, and then back to the end face welding step; X- ray inspection pass is flat end faces chamfering After softening, it enters the pipe end shaping station.

6 ). Pipe end shaping is aimed at reducing the diameter of the pipe mouth after welding due to thermal deformation. If the pipe end is not qualified, it will be shaped into the ultrasonic flaw detection station. In order to avoid a lot of waste, this production line is equipped with a 1250t internal expansion type. Tube end shaping machine, equipped with a 180 ° tube spinner, can meet the tube end shaping at any end of the composite pipe;

7 ) Enter the combined ultrasonic flaw detector (endoscope) of the inner tube and the outer tube to inspect the steel pipe, and put the endoscope probe on the inner tube flaw detection head for internal defect inspection;

8 ) Enter product area or waste area;