Total station search

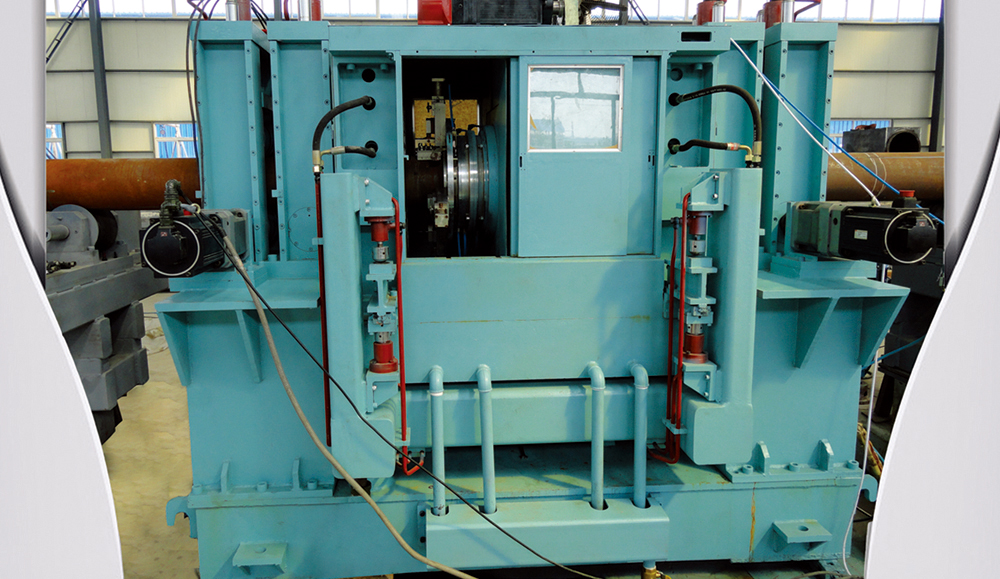

Hydraulic pressSteel tube hydrostatic testing machineSteel pipe hydraulic press

Steel tube high-speed ultrasonic flaw detector is a new type of flaw detection equipment jointly developed by our company and Tianjin University and Beigang Institute of Non-destructive Testing. It adopts the method of high-speed rotation of the probe and linear movement of the pipe. It is always consistent with the center of the steel pipe; the probe box is universally tracked and contacts the pipe body to ensure that the position of the probe and the pipe body is always the same. The equipment has a high degree of automation, automatic loading and unloading, and automatic adjustment of the center according to the specifications of the tube. Shantou Ultrasonic Instrument Research Co., Ltd. is used as the flaw detection instrument to record and store data, detect cracks, folds, and folds in the inner and outer surfaces of the steel pipe, horizontally and vertically. Defects and thickness measurement such as delamination and scarring, and marking the defect positions with different colors, it is suitable for inspecting seamless steel pipe production lines with high quality requirements and large production capacity.

Adapt pipe diameter Φ60∽Φ600, wall thickness 4∽100mm, rotation speed of probe disk is 400r / min, detection speed is 30m / min, thickness measurement accuracy is ± 0.1mm. The dead zone is 150mm. Marking error ± 50mm. There is a prototype of Φ139.7 样 Φ244.5.